When cruising on board a state-of-the-art superyacht, owners and guests rightly rely on having electricity on demand for a plethora of different entertainment systems and operational equipment – all of which must be provided by the yacht’s generators and on-board power systems.

While guests often take on-board power for granted, changing power requirements, peak load times and spikes in activity mean that demand on the generator system will vary, which begs the question: How do you select the right generator(s) for your yacht? And how have industry developments made these power systems more effective over the years?

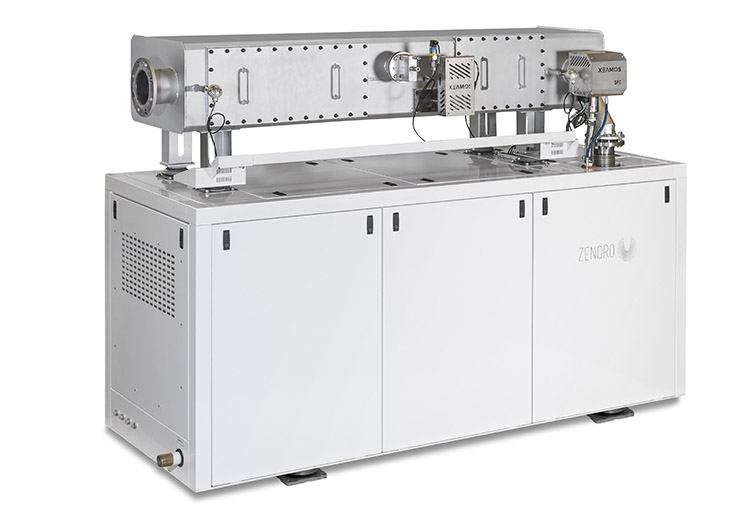

Yachting Pages spoke to Ivo van den Berg at Zenoro, Chris Fower at Fischer Panda UK and Frank Formas of Kohler Power Systems about current developments in superyacht generators, hybrid technology and marine power systems.

Choosing a superyacht generator

Many will know that an over-performing generator can make or break a superyacht, just as an under-performing generator can, making it as much art as science in choosing the ‘right’ set up for a yacht.

To meet the fluctuating electrical needs of a superyacht or pleasure boat in the most efficient, cost-effective and environmentally friendly way, generator manufacturers have had to get more and more creative with their ranges.

Variable-speed marine generators

Chris Fower, marine sales and marketing manager at Fischer Panda explained that variable-speed generators are just one such way of meeting these stringent criteria. These seamlessly adjust the speed of the yacht’s engine according to changing power requirements, while the output voltage remains constant from the inverter, making variable-speed generators particularly useful for superyacht engineers and owners.

Ivo van den Berg, business manager at Zenoro said,

Today’s variable-speed and dual-speed generators utilise the yacht’s engine better than ever before, making them more fuel efficient, and also giving an increased lifespan and lower noise levels, with low RPM (revolutions per minute) for low loads and high RPM for high loads. A good example of this is Heesen’s newest superyacht M/Y Home, with her hybrid diesel-electric solution.

Chris continued,

Variable-speed generators, such as Fischer Panda’s Perfect Power iSeries, significantly improve fuel efficiency and also benefit the environment over their traditional counterparts, as the engine is always working correctly loaded, thereby operating at its most efficient with reduced wear and emissions in comparison with those with a fixed-speed RPM.

These AC generators can be connected in parallel and synchronised, ready to work seamlessly together and load-share on demand, meaning that both sets are working comfortably. Each generator is fully independent and can be individually operated. Furthermore, the permanent magnet alternators mean that sets are significantly smaller and lighter than their conventional fixed-speed equivalents: A fixed-speed set of similar capacity is likely to be virtually double the weight and 30% larger in volume. If a large yacht has a couple of generators, it can potentially provide a significant saving in weight and space.

There is also a safety/performance advantage for some multi-hull vessels, which may benefit from installing multiple smaller generators to improve weight distribution.

Load management software

Over at Kohler Power Systems, its new Decision-Maker 3500 controller has been integrated into its marine generators ensuring they are equipped with paralelling and load-management software for automatic paralelling of two or more generators without the cost and extra footprint of switchgear.

Frank Formas explained, “While load requirements have increased on superyachts due to advanced electronics equipment, on-board space is still at a premium. Our new paralelling controller matches power capacity with load needs to eliminate under-loading and over-fueling, while conserving space, decreasing fuel costs and reducing equipment maintenance.

Basically, when the first generator’s load is light, the second generator automatically drops off, and, when the load is heavy, it automatically comes back online and provides the power needed to carry the load. The high-pressure rail fuel system ensures proper engine combustion, providing just the right amount of fuel at the right time to reduce the effects of poor performance. Combined, this means there is no need for expensive load banks, exhaust treatment systems or costly repairs.

Increasing marine generator efficiency with hybrid technologies

Just as in the propulsion market, hybrid generator systems have carved out a space in the superyacht industry, with Zenoro and Northern Lights (to name a few) manufacturing fixed and variable-speed products.

Ivo explained that its partner, De Keizer Marine Engineering has developed a hybrid-like solution it calls ‘DekaSmartGrid’. This ensures marine generators are used more efficiently, optimising the use of power on board by combining technology and software to ensure that any surplus power is stored in batteries for later use. This results in lower fuel consumption and reduced soot build-up in the generators, enhancing the lifespan and performance of on-board generators.

Increasing comfort on board with ‘clean air’ engineering

A demand for ‘clean air’ and soot free technologies is also driving change in the marine generators industry – powered namely by owner expectations for clean air on board, according to Zenoro, as well as legislative rules.

With owner demand and Emission Control Areas (ECA’s) set to increase, NPS Diesel and Solfic Energy & Emission recently joined forces to introduce XEAMOS after-treatment exhaust systems for marine engines.

Ivo explained,

Soot-free diesel exhaust gases from superyacht generator sets are becoming more and more common standard; not initiated by legislative rules, but driven by owner satisfaction, to avoid VIP guests experiencing particulates on deck, greasy deposits in swimming pools and the smell of diesel fuel.

Most generator set projects are nowadays supplied with a diesel particulate filter (DPF) to improve comfort levels. Projects over 500GT require a combination of DPF and selective catalytic reduction (SCR) technologies to meet IMO Tier III NOx emission standards.

Today, IMO-exempt generators are becoming more popular. As such, 118ekW at 50Hz generator sets can be supplied without SCR, and with optional DPFs to remove soot.

Improving generator installation in superyacht refit

As well as generators becoming more efficient, the way in which they are selected and installed in superyacht refit projects is changing.

When a shipyard or yacht builder works to select the generator for a new-build yacht, the required load will obviously be theoretical, relying on the learned experience of the chosen electrical specialists to predict the required power of the superyacht in hand, based on its size, purpose and selected electrical equipment.

Replacing a marine generator that’s clocked up 20,000+ running hours during refit is therefore arguably somewhat of an easier project, in that the current load can be tracked prior to refit, and any new load accurately predicted, taking out the guesswork and essentially selecting the right generator for you. This allows for old and often oversized generators to be downsized, updated and made much more economical with current technologies.

With this in mind, there have been developments in generator refits over at Zenoro in recent years, with generator sets supplied disassembled in pieces, often allowing them to be easily loaded and installed on to the yacht in question without cutting any holes in the hull.